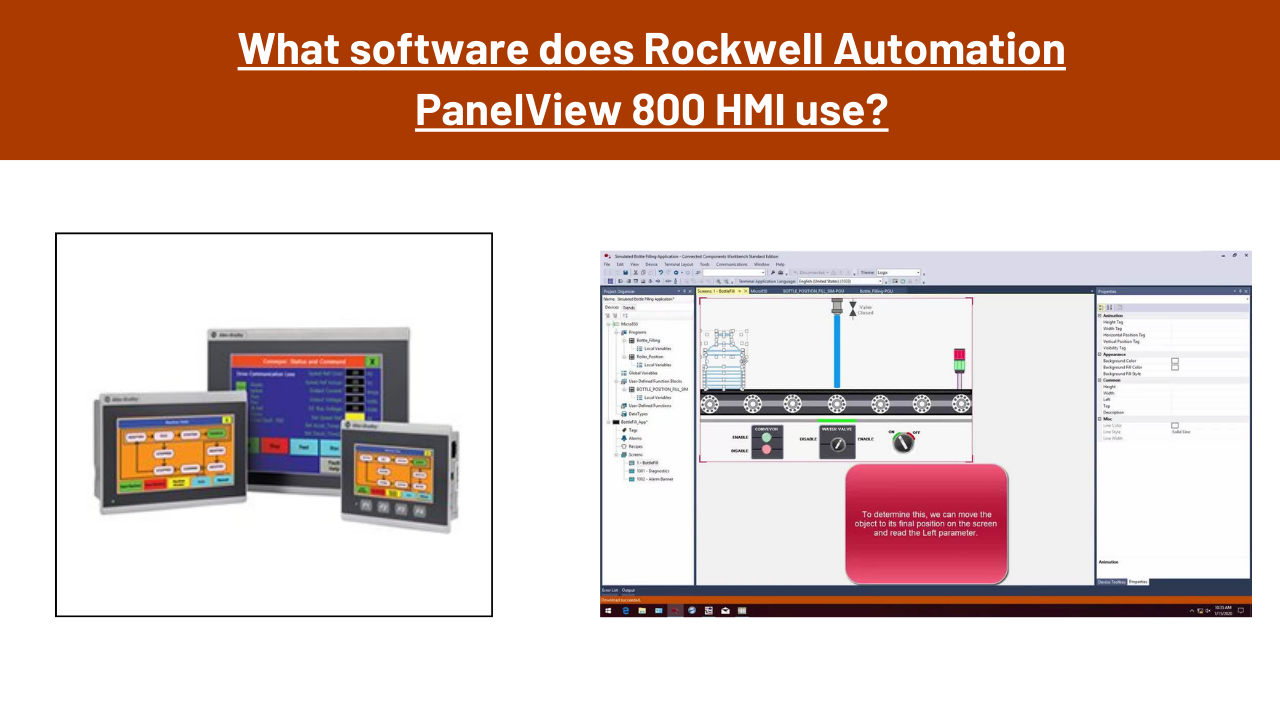

FactoryTalk View Machine Edition (ME) software is used by Rockwell Automation PanelView 800 HMI (Human-Machine Interface) devices to configure and programme them. For the purpose of developing and maintaining HMI applications for Rockwell Automation’s PanelView HMI devices, FactoryTalk View ME is a potent software platform.

Engineers and operators may create and deploy graphical interfaces, watch over and manage industrial processes, and access real-time data using FactoryTalk View ME’s user-friendly development environment. To build logical and interactive HMI applications, the software provides a variety of functions and tools, including:

Graphic Editor:

Users of FactoryTalk View ME can create and alter graphical displays, such as screens, buttons, trends, and alerts, using the program’s graphic editor. To improve the user experience, it provides a large variety of graphic objects, animation choices, and navigational tools.

- Screen Creation: The graphic editor allows users to create the several screens or pages that make up the HMI application. Screens can display real-time statistics, alarms, trends, system status, and other important information in a number of different ways. Users can customise a screen’s size, quality, and navigational options.

Tag-Based Data Structure:

FactoryTalk View ME uses a tag-based data structure to manage and display real-time data from connected industrial devices and controllers. Tags can be configured to represent variables, alarms, and other data points in the control system, allowing for easy data integration and display on HMI screens.

- Tags: The control system’s variables, values, and data points are represented by tags in FactoryTalk View ME. A tag, also known as a PLC tag, a memory location, or a system parameter, is a symbolic name connected to a particular data element or feature.

- Tag Database: All the tags used in the HMI application are kept in the tag database, which is a main repository in FactoryTalk View ME. It uses hierarchical tag organisation to make data administration and navigation simple. Tags can be arranged in folders or according to their purpose, location, or kind.

Alarm and Event Handling:

The software has extensive capabilities for managing alarms and events. Users can set alarm limits, create priority levels, and correlate alarms with particular events or activities. For analysis and troubleshooting, access to the alarm history and event logs is available.

- Alarm Configuration: FactoryTalk View ME allows users to configure alarms based on predefined conditions or events. Alarms can be associated with specific tags or data points in the control system. Users can define alarm limits, priority levels, and acknowledgment requirements. Alarms can be categorized and organized for easier management.

- Alarm Display: When an alarm condition is met, FactoryTalk View ME can visually indicate the alarm on the HMI screens. This can include flashing or color changes on the associated objects or dedicated alarm summary displays. Alarms can be displayed based on their priority, allowing operators to quickly identify and respond to critical events.

- Alarm Logging and History: FactoryTalk View ME supports the logging of alarm data, including timestamps, alarm details, and operator actions. Alarm history can be accessed for analysis, troubleshooting, and compliance reporting purposes. Users can review alarm trends, filter alarms based on criteria, and export data for further analysis.

Check :- Rockwell Automation 2711R PanelView 800 HMI

Trending and Historical Data:

FactoryTalk View ME supports data logging and trending features, allowing users to monitor and analyze historical data trends. It enables the display of real-time and historical data on trend charts and provides tools for data analysis and troubleshooting.

- Trend Object: FactoryTalk View ME offers a trend object that can be added to HMI screens. The trend object allows users to visualize real-time and historical data in the form of trend charts or graphs. It provides a graphical representation of data trends, making it easier to identify patterns, variations, or abnormal behavior.

- Data Logging: FactoryTalk View ME enables the logging of historical data by recording values of selected tags at specific intervals. Users can configure logging parameters such as logging rate, data retention period, and file size limitations. The logged data is stored in a database or file, allowing for easy access and retrieval.

Communication and Connectivity:

FactoryTalk View ME offers various communication drivers and protocols to connect to a wide range of industrial devices, including programmable logic controllers (PLCs), distributed control systems (DCS), and other automation equipment. This enables seamless integration with the control system and facilitates data exchange.

- PLC Connectivity: FactoryTalk View ME supports communication protocols and drivers to connect with programmable logic controllers (PLCs) from Rockwell Automation, such as Allen-Bradley CompactLogix, ControlLogix, MicroLogix, and PLC-5. It allows bi-directional data exchange with the connected PLCs, enabling real-time monitoring and control of industrial processes.

- OPC Connectivity: FactoryTalk View ME supports OPC (OLE for Process Control) for communication with a wide range of third-party devices and systems that comply with the OPC standard. OPC provides a standardized interface for data exchange, enabling seamless integration with diverse devices, such as sensors, actuators, and other automation equipment.

The PanelView 800 HMI from Rockwell Automation provides a complete solution for creating, establishing, and managing industrial HMI systems when used in conjunction with strong software tools such as FactoryTalk View ME, Connected Components Workbench, and Studio 5000 Logix Designer. For current industrial automation, these software tools are indispensable because they offer a plethora of features and advantages that improve the usefulness, efficiency, and dependability of HMI systems.